0%

LEARN MORE ABOUT

VOA INDÚSTRIA

VOA Ferramentaria was founded in 2012, with the objective of supporting the automotive sector in its tooling demands for sheet metal processing (drawing, cutting, and bending operations, as well as prototype and pre-series parts).

We are a tooling company capable of providing our customers with comprehensive stamping tool development solutions, from product engineering, process simulation, complete project, construction, tryout to final production, with approval of stamping tools in the definitive work press, and follow-up from production ramp-up to the complete stability of the production process, proposing solutions and working to improve productivity.

We also have in our portfolio the ability to supply prototypes or batches of parts with low-volume production tooling (soft-tooling and laser cutting) also serving other markets that require low-volume production stamped parts.

CHECK OUT OUR PORTFOLIO

We can also provide specific services: engineering (processes, projects, simulations), small to large 2d and 3d machining, metrology, reverse engineering, stamping parts, press rental, and tryout.

The company has made significant investments for its operations in software, machines, and devices, such as CNC lathes and milling machines, 3D laser cutting machines, tryout presses, three-dimensional machines and laser measuring arms.

CHECK OUT OUR PORTFOLIO

We can also provide specific services: engineering (processes, projects, simulations), small to large 2d and 3d machining, metrology, reverse engineering, stamping parts, press rental, and tryout.

The company has made significant investments for its operations in software, machines, and devices, such as CNC lathes and milling machines, 3D laser cutting machines, tryout presses, three-dimensional machines and laser measuring arms.

OUR TEAM

| Engineering |

| Machinery |

| Tooling |

| Building prototypes |

| 11 |

| 25 |

| 45 |

| 5 |

| Employees |

| 14 |

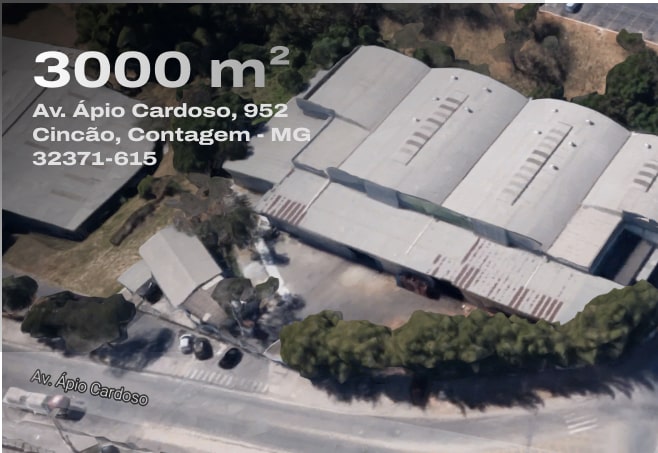

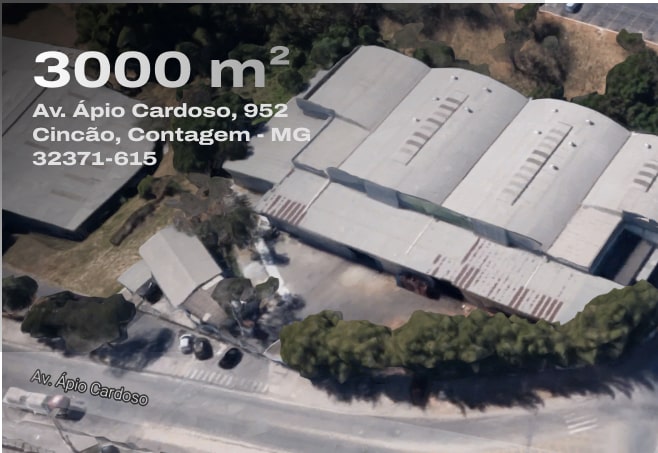

PRODUCTION CAPACITY

The company operates from designing the process and project stages to the final tryout (finishing).

PRODUCTION CAPACITY

The company operates from designing the process and project stages to the final tryout (finishing).

EXPERIENCE WITH LARGE CUSTOMERS

Benchmark

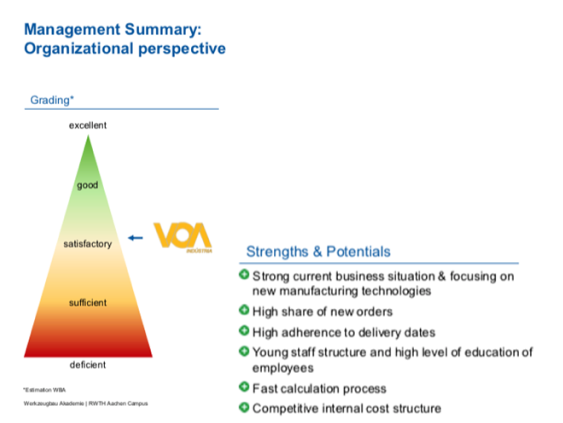

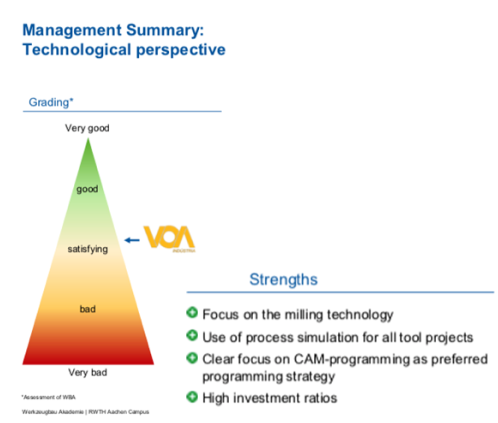

Last year, Voa participated in a benchmark process conducted by the WBA Tooling Academy Aachen in Germany and IPT Brasil, where we were compared with tooling companies from all over the world. The result was very positive and demonstrates that we are on the right path focused on state-of-the-art tooling.

INDUSTRY 4.0 AT VOA

FERRAMENTARIA

Tooling process optimization is already addressed in multiple ways at VOA

ENGINEERING

In engineering, VOA uses state-of-the-art software, such as AutoForm, helping both in the bidding and in the simulation of stamped parts, as well as Siemens NX for projects and the TEBIS Milling program.

ENGINEERING

In engineering, VOA uses state-of-the-art software, such as AutoForm, helping both in the bidding and in the simulation of stamped parts, as well as Siemens NX for projects and the TEBIS Milling program.

LEARN MORE ABOUT OUR ENGINEERING

Transfer, Tandem

and progressive stamping

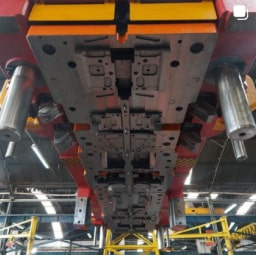

We develop tooling for stamped items focused on the automotive sector. We have a comprehensive structure for the development of transfer, tandem and progressive tooling

Request a quote

We want to better understand the needs of your company to find out how we can help you. Contact us and request your free quote.